Summary: Effective thermal management in electronics manufacturing is essential to ensure consistent performance, prevent premature component failure, and extend product life. By integrating advanced materials such as thermal interface products, manufacturers can significantly enhance the reliability and efficiency of their electronics.

Managing heat is one of the most important factors in the long-term performance and reliability of electronics. Unfortunately, it’s also one of the most overlooked factors. As devices become smaller, faster, and more powerful, efficient thermal management in electronics is critical for not only functionality but safety, energy efficiency, and longevity.

From design to final assembly, every stage of the electronics manufacturing process offers opportunities to control heat buildup. Modern thermal management solutions are evolving rapidly, giving manufacturers new tools and materials to ensure that temperature remains within safe operating ranges for sensitive components.

Role of Thermal Management in Electronics Manufacturing

Heat is the natural byproduct of electrical activity. In high-performance devices, such as those used in industrial automation systems, automotive control units, and other small electronics, heat accumulation can degrade semiconductors, alter signal timing, and even cause catastrophic component failure.

In manufacturing environments, engineers must address heat dissipation early in the design process to prevent performance degradation over the product’s lifespan. This involves understanding thermal paths, material conductivity, and environmental exposure, all of which affect system reliability.

Advanced Techniques for Thermal Management

Fortunately, electronics manufacturers have multiple strategies to manage heat effectively throughout the production process. Let’s take a closer look at your options.

1. Thermal Simulation and Predictive Modeling

Before production even begins, engineers can use thermal simulation software to predict heat flow and identify potential problem areas on board or within an enclosure. These tools reduce costly redesigns and enable more efficient thermal architecture from the start.

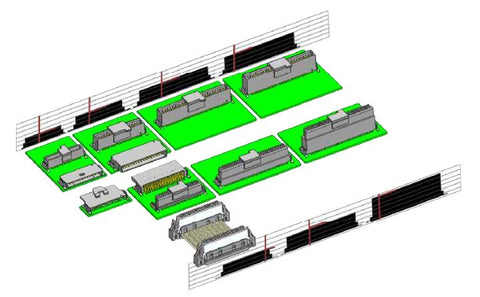

2. Thermal Interface Products

Thermal interface products offer excellent thermal conductivity, reducing resistance and ensuring consistent heat transfer away from processors or power components. They are ideal for small components and in applications where a fan would be too bulky, noisy, or provide insufficient heat transfer. Imtron can help you source the right thermal interface product for your part.

3. Heat Sinks and Spreaders

Heat sinks and heat spreaders are passive components that dissipate heat from the source into the surrounding air. Precision-machined aluminum or copper heat sinks can be customized to match PCB layouts, while graphite and vapor-chamber spreaders distribute heat evenly across critical areas to reduce hotspots.

4. Phase-Change and Advanced Cooling Materials

Phase-change materials store and release thermal energy, stabilizing component temperatures under fluctuating workloads. These technologies are ideal for high-density systems or environments with limited airflow.

5. Additive Manufacturing for Custom Thermal Solutions

Electronics manufacturers can take advantage of 3D printing to design custom heat sinks, housings, and cooling channels for their devices. Additive manufacturing offers design freedom that improves performance and reduces weight.

As electronics continue to shrink and power densities rise, thermal management will become even more crucial. Electronics manufacturers should embrace thermal management as a core design principle that improves efficiency and reliability. Partner with Imtron to source the latest, most effective thermal management solutions for your products. Get in touch with our expert team today for support.

Thermal Management for Electronic Manufacturing FAQs

Why is thermal management important in electronics manufacturing?

Heat buildup can damage sensitive components, cause signal instability, and shorten product lifespan, making effective thermal control vital for performance and safety.

What are thermal interface products (TIPs), and how do they help?

TIPs ensure consistent heat transfer away from processors or power components. They are ideal for small components and in applications where a fan would be too bulky, noisy, or provide insufficient heat transfer.

How does simulation improve thermal management?

Thermal simulation allows engineers to predict heat flow before production, enabling early design optimizations that reduce the risk of overheating and costly redesigns later.

How can integrating thermal management early in the manufacturing process improve reliability?

By addressing heat dissipation during design and assembly, manufacturers can optimize material selection, reduce thermal stress on components, and ensure consistent performance across the product’s entire operational life.